EBC Upgrade Brake Pads (Multiple Options) - MK2 Focus RS

- Vendorebc

SKU: DPX2055

£85.62 Incl. VAT

Shipping Costs Calculated at checkout- Price Match Guarantee

- Speedy Shipping

- Lowest Price Guarantee

FREE SHIPPING ON ALL EXHAUSTS (UK Mainland Only)

TrustPilot Rating 4.6 ★★★★☆ - EXCELLENT - Read our 840+ Reviews

SKU: DPX2055

£85.62 Incl. VAT

Shipping Costs Calculated at checkoutThe perfect quality daily driver pad option.

These premium quality British made pads are designed to meet or exceed the performance of any OEM pad.

The EBC Brakes Ultimax range are long lasting, high friction pads designed for normal urban driving at all speeds on prestige cars, 4x4 and light trucks.

Ultimax pads feature centre slots, edge chamfers and Brake-In surface coating to condition discs after installation and help to quickly deliver stopping power on new pads.

Hardware and wear leads included where fitted as standard.

All Ultimax pads are tested to and carry ECE R90 approval making them 100% equivalent to original parts with a stronger brake effect.

Tests at the MIRA research facility prove that these pads typically stop faster then OE.

NOT FOR TRACK USE.

Choose Greenstuff or Redstuff for fast street use, Yellowstuff for track use and Bluestuff or Orangestuff for race use.

EBC Brakes Greenstuff is a high friction Kevlar based pad compound designed to improve stopping power on lighter cars such as hot hatches and sport saloons in spirited highway driving. The Greenstuff range delivers improved brake response from hot or cold and emits less dust than equivalent semi-metallic pads.

In tests, Greenstuff has been proven to stop a vehicle 20 feet shorter than using stock pads. Greenstuff pads are fully shimmed, chamfered and slotted for silent braking and also feature the EBC Brake‐In surface coating to accelerate pad bed‐in after installation.

THESE PADS ARE NOT FOR TRACK USE.

For heavier and faster cars in street or motorway driving, the best choice is EBC Brakes Redstuff or for fastest street use or track driving of any kind, try EBC Brakes Yellowstuff, Bluestuff or Orangestuff which are designed for this purpose.

All EBC compounds are performance enhanced with CERAMIC GRANULES making them a true premium upgrade pad range for all vehicles.

Excellent type approved upgrade pad for prestige imports and European/Asian cars

Featuring Brake-In surface coating for instant bed-in after installation

Low dust pad which gives a brake improvement of 20-25% on OE

Minimal rotor damage characteristics

These pads contain NO steel fibers

Ceramic particles (not fibers) enhance the aramid fibre formulation used in EBC Brakes Redstuff to deliver powerful and long lasting silent braking for the discerning driver.

An ideal upgrade delivering great brake response and feel from first application of the brakes.Redstuff pads are NOT FOR TRACK USE. See Yellowstuff, Bluestuff, or the new RP1 and RPX full race pads for track use.

Includes NVH counter weights for reduced noise and vibration

EBC Brakes Yellowstuff compound is a high performance road pad that is also suitable for track use and works really well from cold.

If you want the ultimate in high friction braking, this is the pad to choose.

Brakes feel superb from first touch of the pedal and stay effective right up to race temperatures.

EBC Brakes Yellowstuff is designed for faster, higher horsepower cars where maximum stopping power is the prime requirement as well as for track use.

The dust rating is less than OEM parts.

Where necessary, all pads come with edge chamfers, noise reduction shims and OEM hardware.

All EBC Brakes Yellowstuff pads feature the Brake-In surface coating which helps pads to seat quickly after installation.

All EBC compounds are performance enhanced with CERAMIC GRANULES making them a true premium upgrade pad range for all vehicles.

A great all round sport and race pad used by many for fastest street and also trackday events

Bluestuff material exhibits a 0.52μ stable friction once bedded stable up to a slightly higher 550℃/1000℉ than its sister compound yellow but with the benefit of 30% longer life than yellow.

Blue has been a trackday favourite for years and is the spec pad for the BMW 318i Cup series throughout Europe.New formula is copper free to conform to upcoming environmental legislations

0.52μ stable friction once bedded

Strong initial bite ,work from cold

Zero rotor damage

Copper free for ECO compliance

Excellent upgrade pad for SUV and armored vehicles in street use

Pads do require careful bedding in before track use.

Bluestuff also has good bite from cold and is an Aramid fibre base offering reduced rotor wear and has been popular with Trackday drivers due to its longer wear life than Yellowstuff, it's stablemate.

Includes NVH counter weights for reduced noise and vibration

Developed as a full race pad with a high friction level that increases with temperature.

This material works best on light to middleweight high powered race cars where a higher fade resistance and wear life is desirable compared to Yellowstuff. Despite having an acceptable cold friction making this material street usable, the hot friction is deemed too high for ECE R90 approval and therefore this material is not road legal within Europe.

All EBC compounds are performance enhanced with CERAMIC GRANULES making them a true premium upgrade pad range for all vehicles.

EBC Racing's RP‑1 compound is an ultra‑high performance track and race pad designed for high performance vehicles driven hard on track. RP‑1 has a very stable friction coefficient of 0.45μ up to and beyond 750℃, making it an excellent performer for even the most demanding vehicle applications.

Due to its relatively high friction coefficient, RP‑1 is not Reg 90 homologated for road use within Europe and is therefore illegal for use on the public road. Unlike some other race pads on the market, RP‑1 offers a usable cold friction of 0.35μ below 100℃ meaning it can be safely used as a road pad for non‑European markets where Reg 90 homologation is not mandatory. At 100℃ the friction gently climbs to 0.45μ and stays there up to and beyond the designed upper working temperature range of 750℃.

RP‑1 boasts good pad life but the unique characteristic of RP‑1 is that it boasts exceptionally low disc wear, lower than virtually all other competitor race materials tested by EBC Racing. RP‑1 has a progressive pedal feel with unrivalled modulation. RP‑1 does not have the snatchy pedal feel or high levels of noise often associated with other race pads on the market.

Compared to EBC Racing's other track pad RP‑X, RP‑1 has a 25% reduction in friction coefficient across its working temperature range making RP‑1 the more suitable choice for light‑medium weight cars, cars with non EBC Big Brake Kits fitted, or vehicles with no ABS. For heavy or inherently under‑servoed vehicles which suit a very aggressive pad, EBC Racing's other track material RP‑X may be preferable.

EBC Racings' RP‑X compound is an ultra‑high performance track and race pad designed for performance vehicles driven hard on track and for dedicated race cars. RP‑X has a very stable friction coefficient of 0.55μ up to and beyond 850℃, making it an excellent performer for even the most demanding vehicle applications.

RP‑X also has a high friction level from cold, requiring no warmup to achieve maximum braking effect which makes this material well suited for sprint race and hill climb events. Although RP‑X is not R90 homologated for use on the public roads in EU member states, the fact this material possesses excellent cold performance means RP‑X can be safely used for driving to/from motorsport events (where local laws permit).

EBC Racing does however emphasise that RP‑X has been developed for peak on‑track performance, meaning higher levels of brake dust and brake noise should be expected. RP‑X has comparable disc wear to many other popular track/race materials, however RP‑X disc wear is considerably greater than EBC Racing's other track pad RP‑1 which results in high levels of brake dust.

Compared to RP‑1, RP‑X has a 25% increase in friction coefficient across its working temperature range with a much more 'positive' initial bite. This characteristic potentially makes RP‑X more suitable on heavy or inherently under‑servoed vehicles. For light‑medium weight vehicles, cars with non EBC Big Brake Kits fitted, or vehicles with no ABS, the less fierce nature of EBC Racing's other track material RP‑1 may be preferable.

The Ultimax, Greenstuff, Yellowstuff, and Redstuff EBC pad grades come with a brake in coating that scrubs the rotor surface, accelerates pad seating times, and provides a strong brake effect for the first 100 miles of use as your pads seat themselves. After the first 100 miles or so, unless you are going to drive aggressively, there is nothing more to do meaning – most drivers happily use and enjoy their brake’s excellent performance for tens of thousands of miles after this point. If that’s your way of driving nothing more needs to be explained. Just enjoy your brakes.

Fast street driving

If you drive aggressively or in a “Spirited” fashion on roads where it is safe to do so, after seating the pads to your rotors and certainly not before 300 miles of use , you should be prepared for the pad to emit an odour or even exhibit some smoke as the pads burn off what we call “surface volatiles”. Many faster drivers experience this in harder braking and criticize the pad whereas in fact, this is only part of the final high-end bedding in process as the pads see rotors temps of 400-500C for the first time (not normal in everyday driving).

Once seated any brake pad made by EBC or anyone else, performs better once the pad goes through heat curing or what we call “Green Fade” which happens during its first severe use.

Yellowstuff, although track-capable, is no longer recommended for track use on most cars due to its long bed in the process. BlueStuff is now our recommended entry-level race pad for all vehicles, which as a track hybrid is still great on the street and even better on track. But if you are to use Yellowstuff on the track, follow the below Fade procedures;

Find this complicated? – we tend to agree but all organic pads no matter which brand do need some bedding in to avoid loss of brake and a lot depends on rotor condition, the slightest hollow of the rotor surface will extend the bed in times a lot. So being accurate is important.

How to check if pads have heat cured or chemically bedded – Brake bedding in causes heat and it is strongly advised to monitor this heat using heat paints TWICE during bedding in on Blue and once only with RP series pads. What you do is, apply the heat paints on the outer edge of the rotor, run the pads for enough stops (8-10 stops ) to pass the 430C temperature ( 800 F ) which will be Fade 1, allow a few minutes for the system to cool and take a look at the heat paints to ensure they have passed the 430 C indicator, reapply new heat paints to a different cleaned area of the disc and drive again for 6-8 more hard stops which will take you past Fade 2 where temps should pass 430C (800F) again. Full cool down needed here of at least 20-30 minutes and if you CAN… overnight cool. You need to see the 430C heat paint go off TWICE to have completed Fade 2.

Fitting new discs at pad change also adds to bed in time as even if the discs are flat and smooth the pad and rotor have to “Square up” to each other and achieve 90% surface contact. As you use your pads on either a new or old disc stop every couple of laps and look for the blue-grey contact patch gradually widening across your rotor surface and don’t race until its almost a full sweep contact, any doubts pop the pads out and look at the surfaces to evaluate contact patch sweep.

Why so long to bed in any way – We can (but don’t) sell pads that are classed as soft and bed in even faster or very abrasive pads that scrub away at the rotor, cause lots of dust and give the impression of a shorter bed in time. So the balance here is to make a variety of pads according to the different driving styles and events so that users can choose what’s best for them.

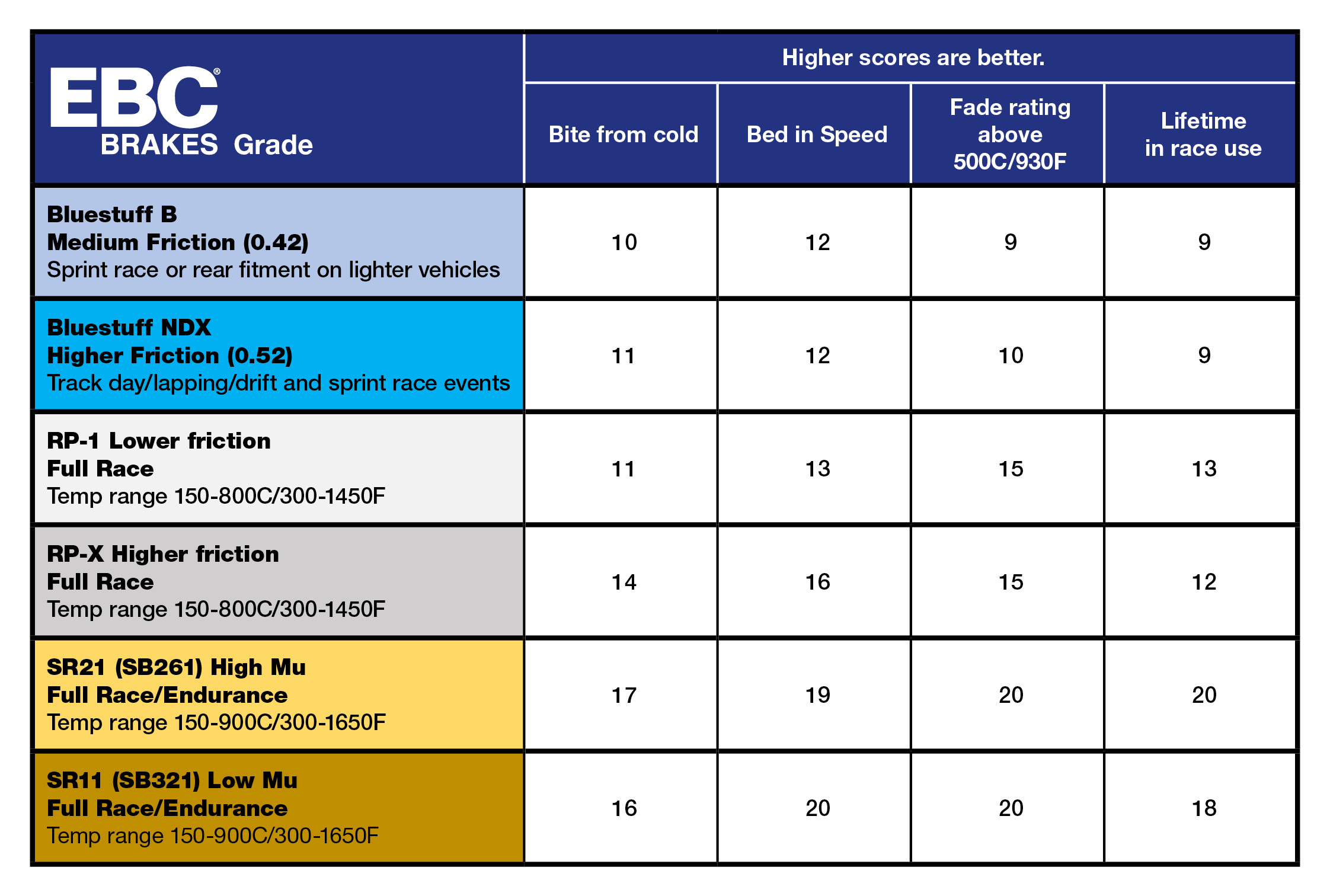

Pads wearing too fast – Trackday or what the USA market call “Lapping” events just doing a few laps to enjoy your car are a tough test on brakes, Extra vehicle weight, seats, and spare wheel, etc and standard calipers make this kind of driving a tough test on brakes and you may need to consider moving up a grade. See this chart as a guide on types of EBC compounds for different driving events

Pads still fading after bed in – it’s not JUST getting the pads flat and parallel it’s about taking them past their green fade point AFTER achieving a good contact band. for this reason, disc heat paints are very useful. Pads should be driven with caution until bedded flat and you have passed this green fade point at least twice and then allowed pads to cool so the disc is below 100C. Green fade only happens on organic pads – much less with our RP pads and not at all with our SR pad range. There are two ways to know if you have passed the green fade point – one is the clever way with heat paints – the second way is to guess… So heat paints are the better option

Green fade points are 400 C or 650 F (Fade 1) and then the same again ( Fade 2) for the two fades required with Bluestuff and 400C/800F just the once for RP series pads RP pads. For this reason, EBC Heat paints first level indicate at a temperature of just over 400C/800 F so that once this paint changes colour, one fade cycle is done.

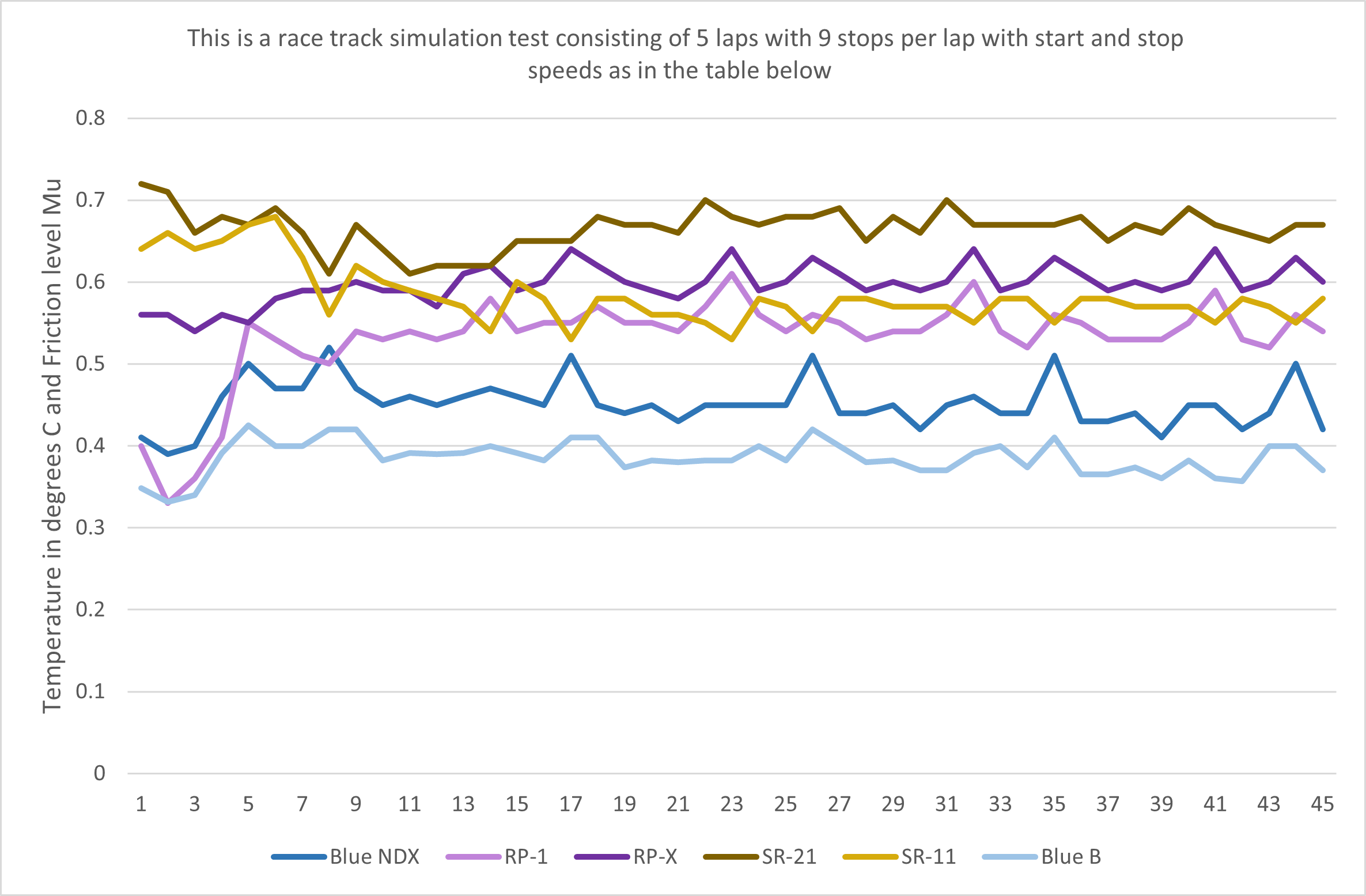

Comparison of friction levels of the main EBC race materials below

The graph should not be confused with a “ fade test “

Any falloff in friction depends on the deceleration amount from V1 to V2 – and heavier stops see more fall off.

Still, in every case, the brake effect is still very significant and reliable

The test is a made-up lap of 9 stops repeated 5 times to give 45 stops in total.

All stops are at 0.7G but have different brake-on and brake-off speeds as shown below (in km/h) – the slower stops tend to produce higher friction levels irrespective of the material which is what gives the variability.

| Stop | V initial Km/hr | V final Km/hr |

| 1 | 224 | 144 |

| 2 | 200 | 80 |

| 3 | 208 | 128 |

| 4 | 192 | 64 |

| 5 | 144 | 48 |

| 6 | 208 | 128 |

| 7 | 216 | 112 |

| 8 | 144 | 40 |

| 9 | 192 | 96 |

Surprisingly many drivers don’t pay enough attention to fluid. A high temp fluid such as EBC BF-307 which is an extremely pure glycol fluid and has a dry (new) boiling point of 307C ( 580F ) should be used, change fluids regularly in track use to maintain firm brake pedal, avoid vapor lock and deliver a linear brake response. Fluids should be changed every two years for normal street use and every 2-3 track events for track-day and every event for full hard race use.

EBC strongly recommends the use of Disc heat paints to monitor disc temperature and caliper heat strips in racing to check caliper is not overheating. If calipers are dragging temperatures can rise above the seal upper limits and damage seals. Sliding single piston calipers should always be serviced ready for track driving as often sticking or seized calipers cause blame to be placed on the pad compound in error.