Description

If your car is fitted with adaptive cruise control, we can additionally supply you with a billet bracket and fixings to enable the relocation of the ACC radar. Simply select the ACC option in the drop down menu above. No re-coding of the unit should be necessary.

Following on from our very successful intercooler for the RS3 8P chassis, the Forge intercooler for the RS3 8V chassis builds on our reputation for delivering cores that offer real-world increases in power and temperature drops.

Whilst the 8V chassis shares many components with the older 8P, the space available behind the bumper is a different shape and the crash bar has also changed. This required a whole new intercooler and crash bar setup for this latest chassis*

The RS3 8V core is a huge 640x250x100 and of bar and plate design. This gives it a huge 55% more surface area than stock, and an even more impressive 94% more volume. The end tanks are made with integrated pipes in order to retain the stock boost hoses, though you can also replace the hoses with our FMKT024 boost hose set if you so wish. Just like on the 8P chassis, we supply a genuine Audi RS3 crash bar which we modify in house in order to accept the new larger core, then finish both the crash bar and core in our standard black crackle finish powder coat for maximum longevity.

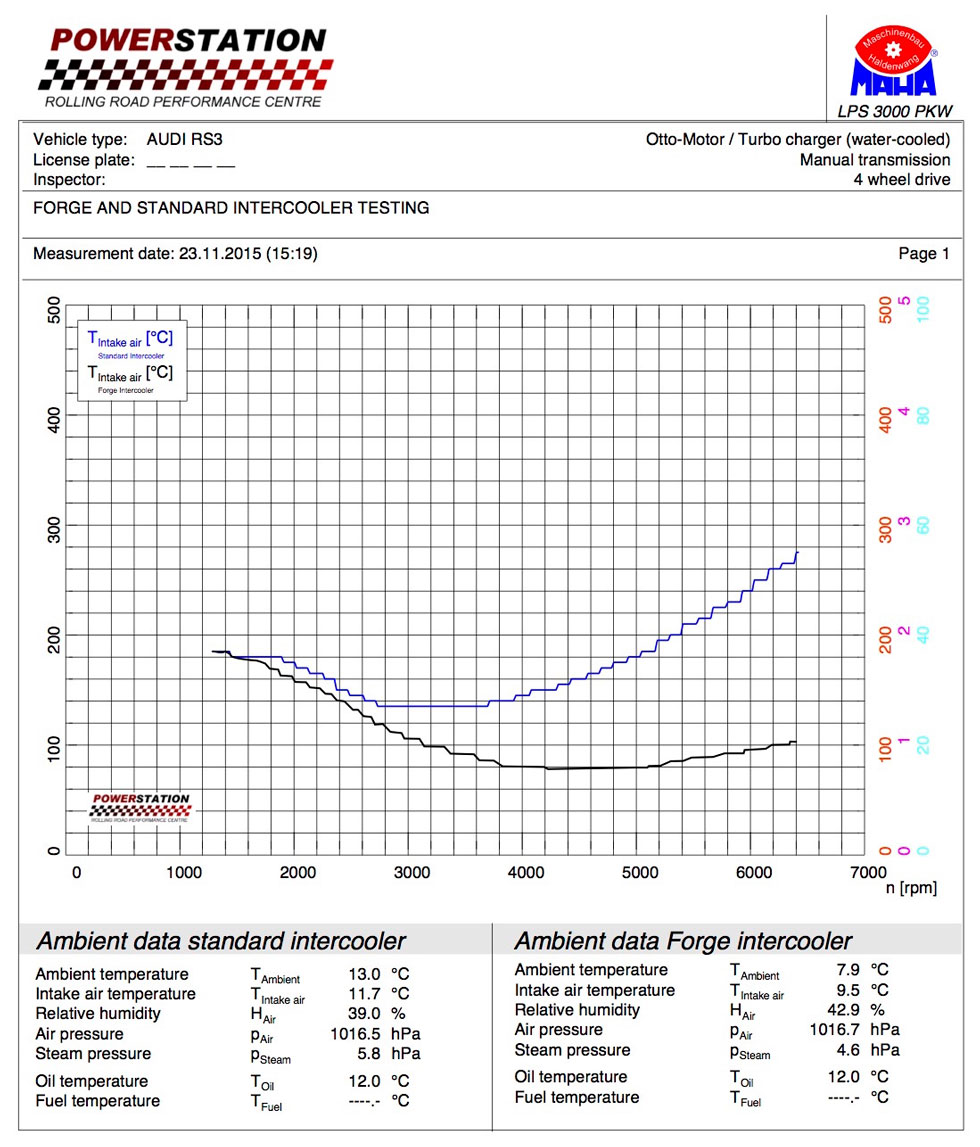

As shown in the graph above, for both tests we let the car heatsoak on the dyno until the radiator fans tripped on and off (which gives an inlet temperature of 36 deg C), then do a dyno pull from there. This gives a more consistent result and reflects real-world driving conditions more accurately. You can easily see the Forge intercooler cools much quicker and delivers a much greater drop in temperature compared to OEM.

On the standard car we tested on, it made 362bhp completely stock (so largely in line with what Audi quote) with a peak intake temperature of 58°C. With just this intercooler fitted and no other modifications, the same car made 386bhp with a peak inlet temperature of 23°C, a gain of 24bhp and a drop of 35°C. Gains on mapped cars will likely be even more impressive as the stock intercooler core really starts to struggle on stage 1 mapped cars.

The kit contains full instructions for installation, which should take around 3.5 hours, and a complete kit which includes everything needed.

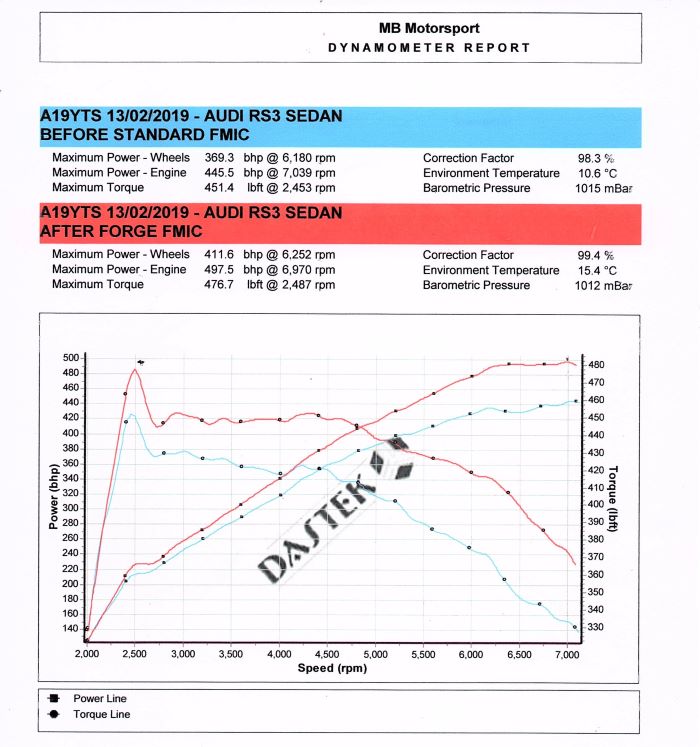

The above dyno graph shows a Forge customer making gains of 52HP with this intercooler

5 / 5 stars - “In short, this product does what it states!” Working with Litchfield and their Technical Partners (Forge) I have conducted extensive testing to support the development of Litchfield tuning packages for the Audi RS3 8V. Whilst the OEM intercooler is “OK”, very rapidly on repeated road and dyno Wide Open Throttle (WOT) sweeps, the air charge temps quickly rise to levels that impact performance (pulling ignition). To extract the full potential out of the tuning packages and increase repeatability of results and improve overall reliability, I turned to Forge and their upgraded front mount intercooler. Not one for just using a product because of “sales speak”, I extensively tested the Forge offering.

The conclusion based on the data logging, mapping and final results was clear. Monitoring charge temps with back to back tests instantly showed us that the cooling efficiency with the Forge product was significantly better. Comparing OEM intercooler charge temps for the coolest first run, against the Forge intercooler on it’s third repeated back to back run (really pushing this comparison with heat soak), the Forge intercooler saw a drop of 18degs peak over the OEM unit (on it’s coolest run with no heat soak). Repeated runs on the OEM intercooler saw the difference widen even more by up to 34degs higher (peak) than the Forge intercooler. Repeated runs between the OEM and Forge intercooler (all completed on the same day) saw the following peak values: OEM - 60degs Forge - 26degs The Forge intercooler also held the lowest charge temperature for longer. This sounds all fine and dandy but what does all this mean in relation to performance? First off Litchfield was able to develop their ECU calibrations without needing to worry about charge temperatures impacting performance.

The car spent many hours on the dyno and completed many back to back runs. Over 30 different calibrations were created and tested. Not once did Litchfield need to let the car cool down between runs. The end result was a solid and repeatable 450+bhp achieved with only their ECU calibration, Forge Intercooler and secondary cat removal. Recently (March 2017), the car at this level of modification (Litchfield Stage 2) achieved a stonking 11.5s @ 118+mph quarter mile run at Santa Pod. This is the quickest time that we are aware of in the UK, for an RS3 8V at this level of modification using normal pump fuel, no weight reduction and on stock tyres. The car also achieved the 60mph sprint in 3.2s, the 100mph sprint in 7.9s and 100-200kmh sprint in 8.9s on this same run. I look forward to seeing how the Forge intercooler will complement Stage 3 development. Watch this space!

Please Note: In line with our policy to constantly review, revise, and improve our product range, the appearance of the product you receive may differ from the one advertised.